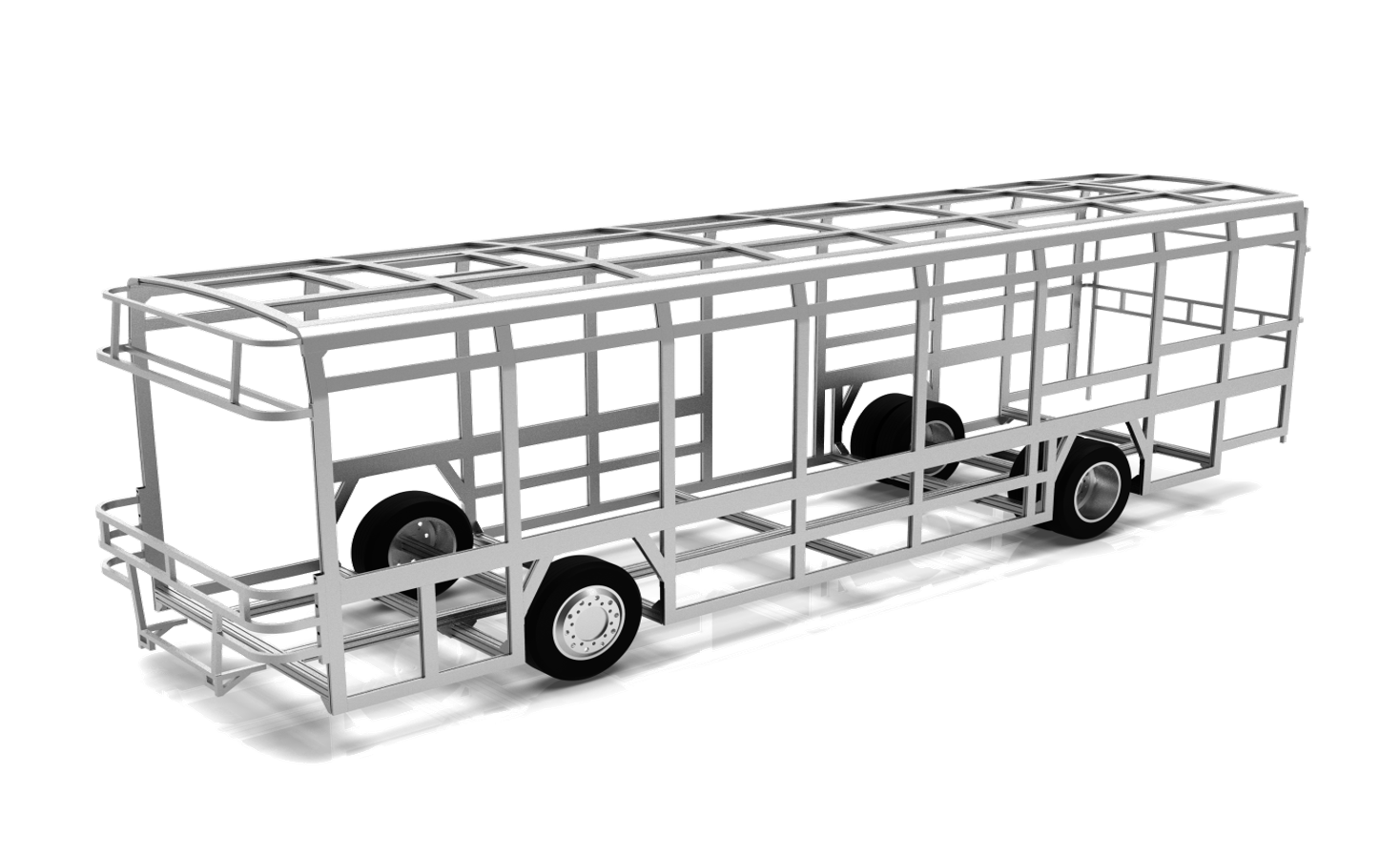

In the passenger car series, aluminum is replaced by steel, and the body frame weight is reduced by 35-45%; it covers all 6-18m single and double-deck models of urban buses to meet the design requirements of the strength and rigidity of the passenger car. It can effectively shorten the braking distance and improve driving safety. The energy-absorbing properties of aluminum can absorb more energy in the event of a collision and protect passengers. The anti-corrosion properties of aluminum alloy can ensure that the vehicle does not rust during the whole life cycle and does not require major repairs. Better surface quality of the car body is conducive to shaping the image of the city.

The weight of the whole vehicle is reduced by 10%, which can reduce fuel consumption by 6-8% and save electric energy by 6-9%. Reduce anti-corrosion and maintenance costs; aluminum recycling brings higher residual value; all-aluminum body design life can be up to 30 years; the entire life cycle use cost is greatly reduced.

| Foreign minister(mm) | Outside width(mm) | Outer height(mm) |

| 6840 | 2550 | 2745 |

| Inner length(mm) | Inner width(mm) | Hurdle height(mm) |

| 6800 | 2450 | 600 |

| Thickness of bottom plate(mm) | Fence opening form | Backdoor form |

| 20 | Sideways | Open door |

| Insertion form | Open box weightKG | Design loadT |

| Insert pile | 1200 | 10 |

The box body is made of high-strength aluminum profiles independently developed and produced, and the surface is sprayed;

The main connection method of the box body is welding and screw connection to ensure the structural strength;

The fence is made of corrugated profiles produced by the company, and the bottom plate is made of profile structures independently developed and produced by the company.

| Foreign minister(mm) | Outside width(mm) | Outer height(mm) |

| 4190 | 2350 | 2525 |

| Inner length(mm) | Inner width(mm) | Hurdle height(mm) |

| 4140 | 2300 | 2300 |

| Thickness of bottom plate(mm) | Door thickness(mm) | Bottom plate |

| 20 | 20 | Aluminum profile |

| Side door | Back door | Lock |

| Right off | Off | Stainless steel/galvanized |

| Open box weightKG(all aluminum) | Volume㎡ | Design load(T) |

| 460 | 21.9 | 5 |

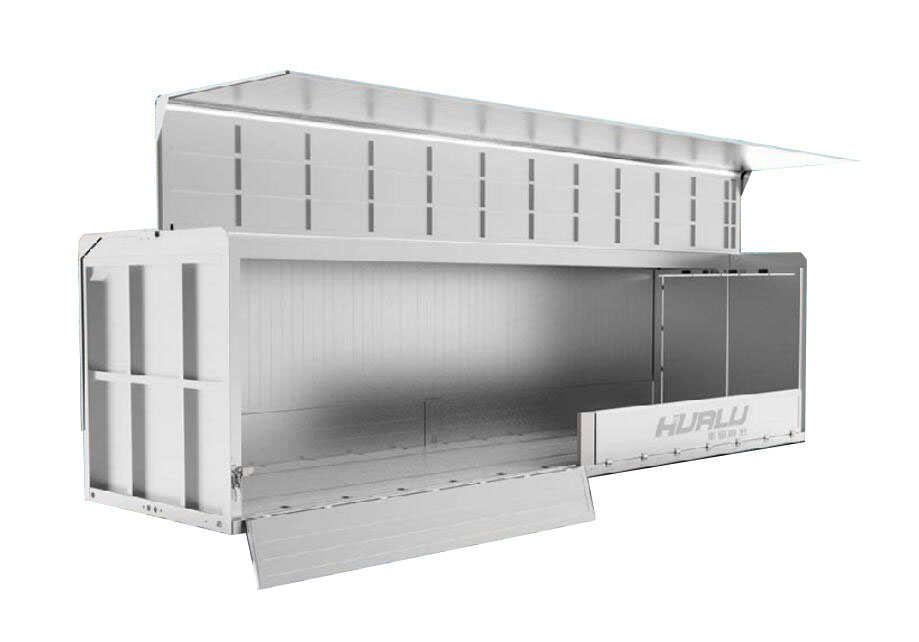

The cabinet is made of high-strength aluminum profiles independently developed and produced;

Riveting, welding, and screwing are the main linking methods of the car body, supplemented by bonding, etc., which is convenient for assembly and maintenance;

A large number of structures are newly developed and optimized from appearance to structure. More than ten patent applications have been submitted.

| Foreign minister(mm) | Outside width(mm) | Outer height(mm) |

| 4190 | 2350 | 2525 |

| Inner length(mm) | Inner width(mm) | Hurdle height(mm) |

| 4140 | 2300 | 2300 |

| Thickness of bottom plate(mm) | Door thickness(mm) | Bottom plate |

| 20 | 20 | Aluminum profile |

| Side door | Back door | Lock |

| Right off | Off | Stainless steel/galvanized |

| Open box weight(KG) | Volume㎡ | Design load(T) |

| 475 | 21.9 | 5 |

The cabinet is made of high-strength aluminum profiles independently developed and produced;

Riveting, welding, and screwing are the main linking methods of the car body, supplemented by bonding, etc., which is convenient for assembly and maintenance;

A large number of structures are newly developed and optimized from appearance to structure. More than ten patent applications have been submitted.

| Foreign minister(mm) | Outside width(mm) | Outer height(mm) |

| 6950 | 2550 | 2910 |

| Inner length(mm) | Inner width(mm) | Hurdle height(mm) |

| 6800 | 2500 | 2500 |

| Fence(mm) | Door panel | Bottom plate |

| 500 | Aluminum profile | Aluminum profile |

| Side door | Back door | Lock |

| Flanks on both sides | Off | galvanized |

| Open box weight(KG) | Volume㎡ | Design load(T) |

| 1800 | / | 10 |

The cabinet is made of high-strength aluminum profiles independently developed and produced;

Riveting, welding, and screwing are the main linking methods of the car body, supplemented by bonding, etc., which is convenient for assembly and maintenance;

A large number of structures are newly developed and optimized from appearance to structure. More than ten patent applications have been submitted.

| Foreign minister(mm) | Outside width(mm) | Outer height(mm) |

| 9820 | 2550 | 2985 |

| Inner length(mm) | Inner width(mm) | Hurdle height(mm) |

| 9780 | 2510 | 2750 |

| Thickness of bottom plate(mm) | Door thickness(mm) | Bottom plate |

| 15 | 20 | All aluminum bottom plate |

| Side door | Back door | Lock |

| No side door | Off | Stainless steel |

| Open box weight(KG) | Volume㎡ | Design load(T) |

| 1595 | 67.5 | 12 |

The main body of the car body is made of high-strength aluminum profiles independently researched and developed, and sprayed with fluorocarbon.

The car body is mainly connected by riveting, culvert, and screwing, supplemented by bonding, which is convenient for maintenance and assembly.

The car body adopts a variety of company's unique cross-section profiles. On the basis of ensuring the capacity of the car body, the structural design is optimized to achieve the goal of lightweight aluminum.

The aluminum skirt board design is added on both sides of the car body, and the overall appearance is beautiful.

Front and rear columns. The structure of the bottom plate, etc., has obtained the patent number:

ZL2020 2 1023900.5

ZL2020 2 1024002.1

The following is the application number:

2020301702313、202030170255、2020301703937、2020301703941、2020301697495 have been authorized

| Foreign minister(mm) | Outside width(mm) | Outer height(mm) |

| 15550 | 3000 | 3225 |

| Inner length(mm) | Inner width(mm) | Hurdle height(mm) |

| 15500 | 2955 | 3060 |

| Thickness of bottom plate(mm) | Door thickness(mm) | Bottom plate |

| 20 | 25 | All aluminum bottom plate |

| Side door | Back door | Lock |

| Right off | Off | Galvanized |

| Open box weight(KG) | Volume㎡ | Design load (T) |

| 3.2 | 140 | 35 |

The main body of the car body is made of high-strength aluminum profiles independently developed and produced, and the side and rear doors are made of high-light steel;

The box body is mainly connected by welding, screwing and riveting, supplemented by bonding, etc., to meet the requirements of box body strength;

The whole vehicle uses a variety of large cross-section profiles, and on the basis of ensuring the volume of the box, the structural design is optimized to achieve the goal of lightweight aluminum.

| Foreign minister(mm) | Outside width(mm) | Outer height(mm) |

| 4285 | 2356 | 1735 |

| Inner length(mm) | Inner width(mm) | Hurdle height(mm) |

| 4165 | 2300 | 400 |

| Thickness of bottom plate(mm) | Floor thickness(mm) | Backdoor form |

| 30 | 20 | Five doors / three doors |

| Insertion form | Open box weight (KG) | Design load(T) |

| Insertion pile | 270/250 | 5 |

It is made of self-developed high-strength aluminum profiles, and the surface treatment can be powder spraying, painting or electrophoresis;

Riveting and screwing are the main connection methods, supplemented by a very small amount of welding, which is convenient for assembly and maintenance;

In terms of structure, in addition to using the product structure of the van structure, the fence part borrows and absorbs Japanese technology and newly designs the prefabricated fence structure. This car uses the following proprietary patents:ZL 2020 2 1023900.5 ZL 2020 2 1024002.1

The following is the application number:2020301697495, all have been authorized.

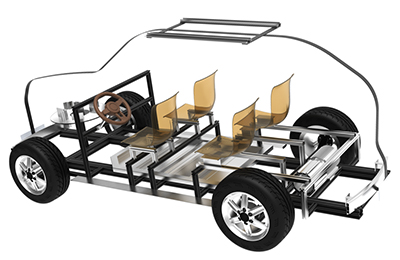

The passenger car model is based on Toyota Prado as a design prototype, showing the application of lightweight aluminum products in passenger cars, mainly including front and rear anti-collision beams, battery packs, side pedals, sunroof slides, and motor housings Products such as frame beams, longitudinal beams, sub-frames, all-aluminum rear doors, door sills and other products are being developed one after another. The company has launched in-depth cooperation with Great Wall Nissan and other companies around related accessories.

Aluminum alloy with its superior strength, lightweight characteristics, flexible design, high corrosion resistance, high recycling rate and other characteristics, successfully reduced the quality of the car, thereby improving the power of the car, reducing fuel and reducing emissions. With the rapid development of new energy models of electric vehicles, the lightweight technology of "aluminum instead of steel" has also become a standard feature. Research by the European Aluminum Association shows that for every 100 kilograms of car weight loss, fuel consumption is reduced by 0.4 liters, and carbon dioxide emissions are reduced by 1 kilogram.